Amazon's Robotic Revolution: How 750,000 Robots are Transforming the Future of E-Commerce

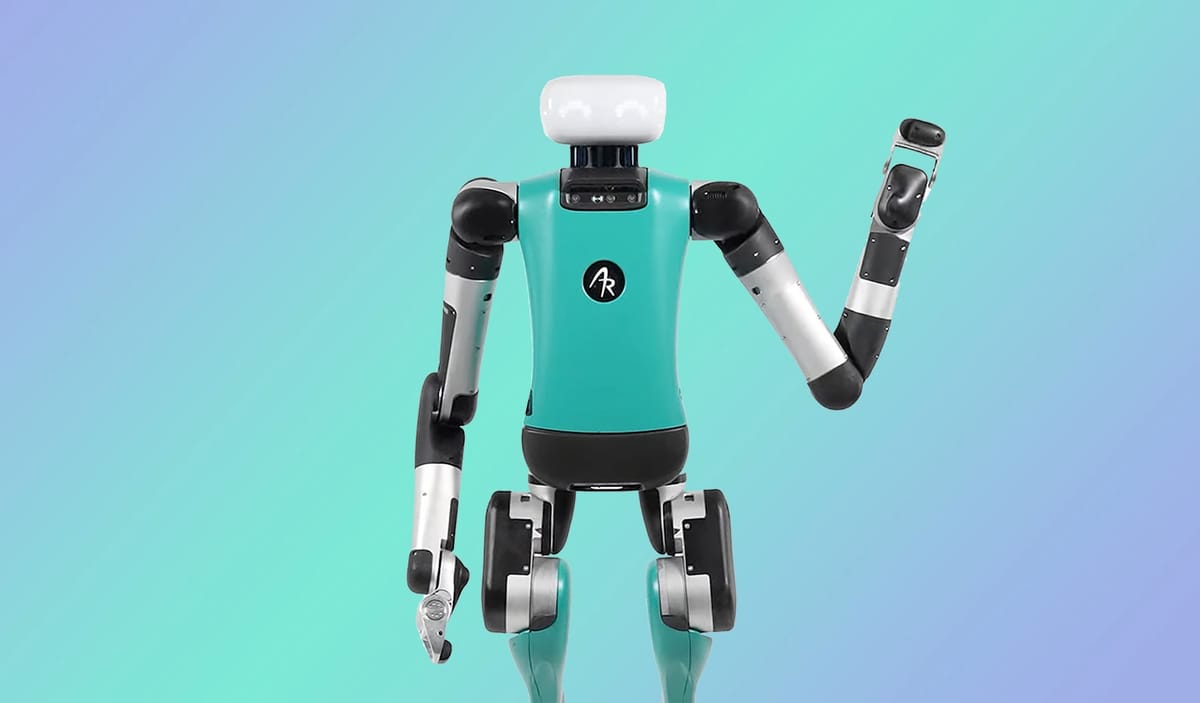

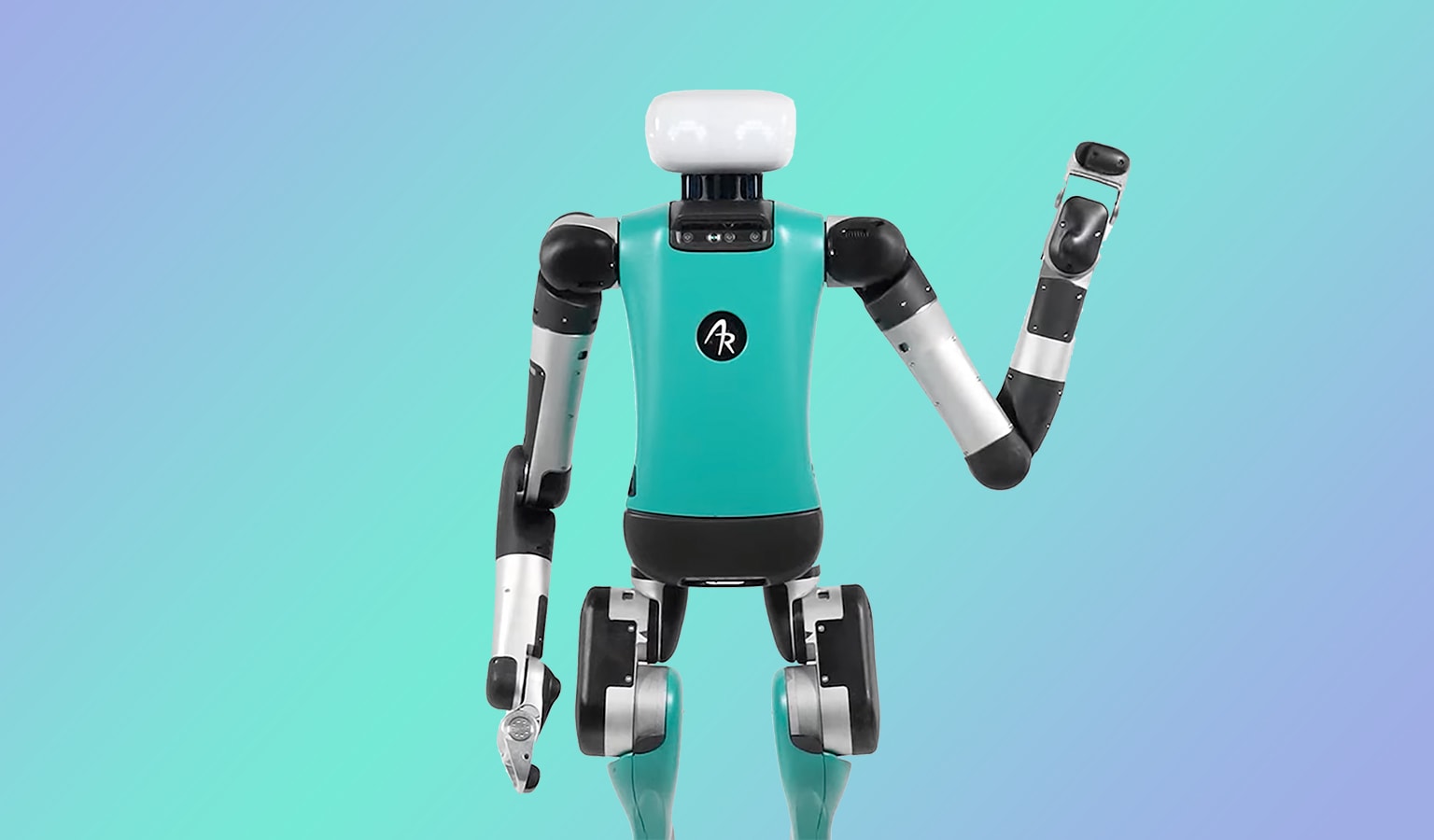

One of the most recent additions to Amazon's robotic arsenal is Digit, a humanoid robot capable of handling and moving items within the warehouse. Digit represents a significant leap forward in the field of warehouse automation.

In the rapidly evolving world of e-commerce, Amazon has emerged as a trailblazer, constantly pushing the boundaries of innovation and efficiency. With the deployment of over 750,000 robots across its global operations, Amazon is revolutionizing the way products are stored, sorted, and delivered to customers. This article delves into the fascinating world of Amazon's robotic ecosystem, exploring its impact on productivity, job creation, and the future of the e-commerce industry.

The Rise of Robotics in Amazon's Warehouses

Amazon's journey into the realm of robotics began in 2012 with the acquisition of Kiva Systems, a company specializing in mobile robotic fulfillment systems. Since then, Amazon has relentlessly pursued the integration of advanced robotics technologies into its warehouses, leading to the deployment of over 750,000 robots worldwide.

These robots come in various forms, each designed to optimize specific tasks within the warehouse environment. From the iconic orange Kiva robots that autonomously navigate the warehouse floor to retrieve products, to the more advanced Pegasus robots that sort and transport packages, Amazon's robotic fleet is a testament to the company's commitment to innovation.

One of the most recent additions to Amazon's robotic arsenal is Digit, a humanoid robot capable of handling and moving items within the warehouse. Developed in collaboration with Agility Robotics, Digit represents a significant leap forward in the field of warehouse automation. With its advanced sensors and artificial intelligence, Digit can navigate complex environments, identify objects, and perform tasks that were previously reserved for human workers.

The Efficiency Boost: How Robots are Optimizing Amazon's Operations

The deployment of robots has had a profound impact on Amazon's operational efficiency. By automating repetitive and time-consuming tasks, robots have enabled Amazon to streamline its processes, reduce errors, and improve the speed of order fulfillment.

In traditional warehouses, human workers spend a significant amount of time walking between shelves to locate and retrieve products. With the introduction of Kiva robots, this process has been greatly optimized. These mobile robots autonomously navigate the warehouse floor, bringing entire shelves of products directly to human workers at picking stations. This eliminates the need for workers to walk long distances, significantly reducing the time and effort required to fulfill orders.

Moreover, robots have played a crucial role in enhancing the accuracy and precision of Amazon's inventory management. The Sequoia robot, for example, is designed to assist in inventory tracking and processing. Equipped with advanced scanning technologies, Sequoia can quickly and accurately identify products, update inventory records, and ensure that the right items are always in stock.

The integration of robots has also led to improved safety standards within Amazon's warehouses. By automating tasks that involve heavy lifting or repetitive motions, robots have reduced the risk of workplace injuries and strain on human workers. This not only benefits the well-being of employees but also contributes to a more efficient and productive work environment.

The Manufacturing and Testing Process: Ensuring Robotic Excellence

To ensure the highest standards of quality and performance, Amazon has established dedicated facilities for the manufacturing and testing of its robots. These state-of-the-art facilities employ a meticulous assembly process that involves a 10-station assembly line.

Each technician on the assembly line is allocated a specific task and given a precise timeframe of seven minutes to complete their part of the robot manufacturing process. This streamlined approach ensures consistency and efficiency in the production of robots, allowing Amazon to meet the growing demand for automation in its warehouses.

Once assembled, each robot undergoes a rigorous testing phase that lasts an additional seven minutes. During this phase, the robots are subjected to a series of tests and simulations to verify their functionality, reliability, and adherence to safety standards. Only robots that pass this stringent testing process are deemed ready for deployment in Amazon's warehouses.

The Human Factor: How Robotics is Creating New Job Opportunities

Contrary to the common misconception that robots are replacing human jobs, Amazon's experience has shown that the integration of robotics has actually led to the creation of new employment opportunities. As robots take over repetitive and mundane tasks, human workers are being upskilled and redeployed to roles that require higher-level thinking, problem-solving, and creativity.

Amazon reports that the introduction of robotics has resulted in the creation of over 700 new job categories within the company. These roles span across various domains, including robot operators, maintenance technicians, data analysts, and software engineers. By investing in the training and development of its workforce, Amazon is ensuring that its employees are equipped with the skills necessary to thrive in an increasingly automated world.

Moreover, the increased efficiency brought about by robots has enabled Amazon to expand its operations and open new fulfillment centers. This expansion has, in turn, created thousands of additional job opportunities in local communities, contributing to economic growth and development.

The Future of Robotics in E-Commerce: Amazon's Ongoing Innovation

As Amazon continues to push the boundaries of robotics technology, the future of e-commerce looks increasingly automated. The company's ongoing research and development efforts are focused on creating even more advanced and versatile robots that can perform a wider range of tasks within the warehouse environment.

One of the most promising areas of development is the integration of artificial intelligence and machine learning into robotic systems. By equipping robots with the ability to learn from their experiences and adapt to new situations, Amazon aims to create a more flexible and resilient automation ecosystem.

Another area of focus is the development of collaborative robots, or cobots, that can work alongside human workers in a safe and efficient manner. These cobots are designed to assist human workers in tasks that require a combination of human dexterity and robotic precision, such as packaging delicate items or assembling complex products.

Looking beyond the warehouse, Amazon is also exploring the potential of robotics in last-mile delivery. The company has already begun testing autonomous delivery robots, such as the Amazon Scout, which can navigate sidewalks and deliver packages directly to customers' doorsteps. As these technologies mature, they have the potential to revolutionize the way products are delivered, making the entire e-commerce experience faster, more convenient, and more sustainable.

Conclusion: Improvements, Efficiencies, and Job Opportunities

Amazon's deployment of over 750,000 robots across its global operations represents a significant milestone in the evolution of e-commerce. By harnessing the power of robotics, Amazon has been able to optimize its processes, improve efficiency, and create new job opportunities for its workforce.

As the company continues to innovate and push the boundaries of what is possible with robotics, it is setting the stage for a future where automation and human ingenuity work hand in hand to deliver unparalleled value to customers. With its relentless focus on innovation and customer satisfaction, Amazon is poised to remain at the forefront of the e-commerce industry, shaping the way we shop and interact with technology for years to come.